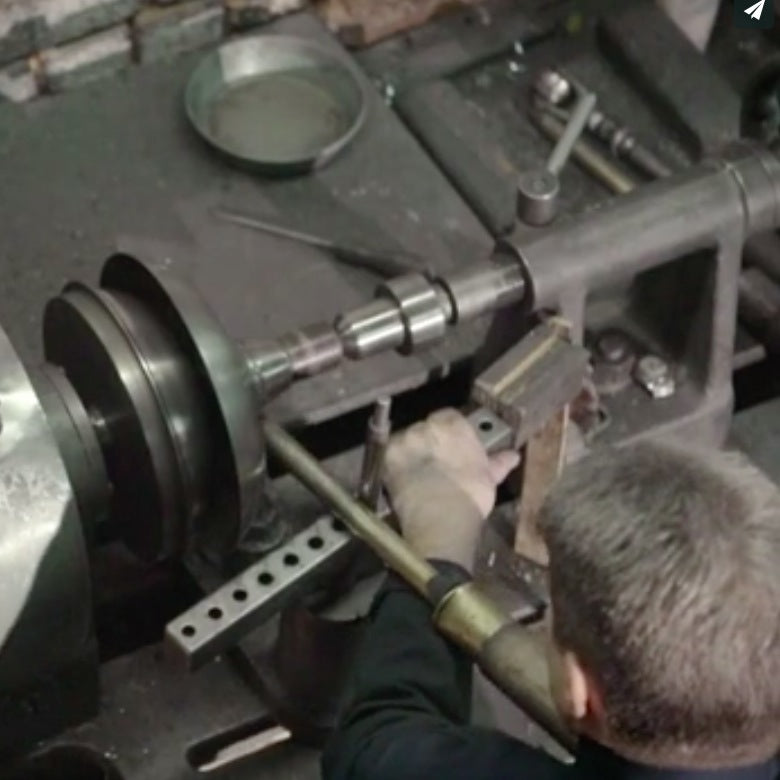

All of our light shades are made entirely in the UK by skilled metalworkers. The film shows our Coolicon shades being meticulously engineered from steel and vitreous enamel.

The raw material for the shades is high quality low carbon steel (or pure copper for the copper shades) which is cut into squares and trimmed into disks. Each metal disk is rotated at high speed and pressure applied so it is moulded over a pattern to form the shape of the shade - a process called metal spinning or spin forming. The force used to form the Coolicon shades is applied by manually using brass levers and rollers. The process is similar to turning clay and it requires a high degree of skill to spin shades of the required shape and uniform thickness. After being spun, the openings in the neck of the Coolicons are laser cut and the shade thoroughly cleaned ready for enamelling. The vitreous enamel is applied as a liquid suspension and the lamp shades are fired after each coat. After the base coat comes the colour before a final glaze is applied. Achieving a consistent colour, thickness and finish of enamel is no less an art than spinning the shades. While many manufacturers have moved production to the far-east to reduce costs, Urban Cottage Industries has chosen to continue manufacturing its light shades entirely and exclusively in the UK to guarantee quality, durability and safety. The entire light shade collection is here. And every shade in the range can be configured as a complete pendant.

Leave a comment

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.