All Factorylux electrical cable is made in Italy to meet rigorous UK and European safety standards.

Many fabric cable manufacturers reduce costs by importing low-cost cable from the far east and then weaving the fabric covering in the UK/EU. The quality of this cable is often poor in terms of finish and flexibility. Because Factorylux cable is made from start to finish in the same factory, production quality can be guaranteed. The cable is supple, curling and coiling easily, and there are a range of exceptionally attractive and durable woven coatings in rayon, polyester, jute and linen.

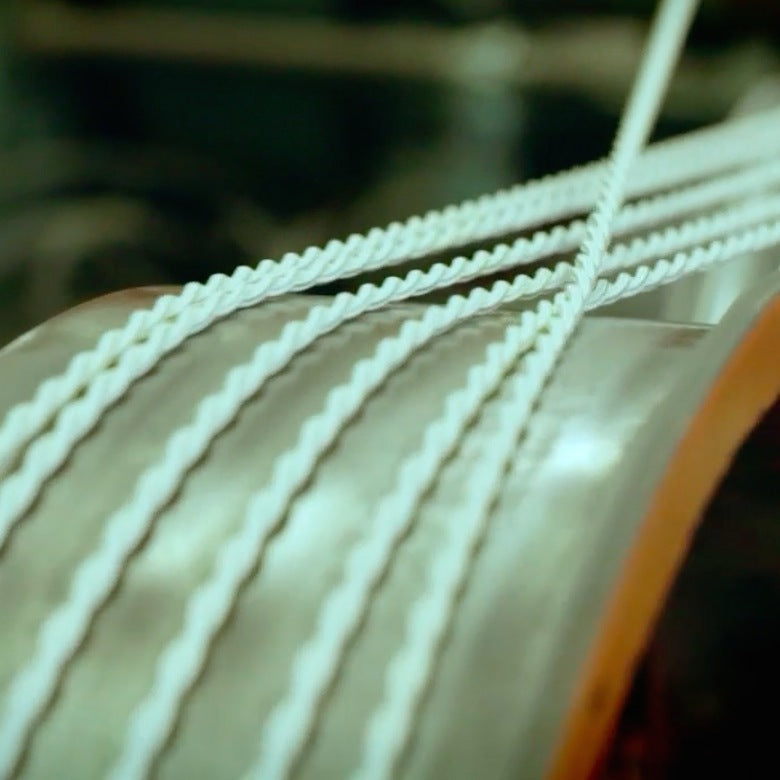

This two minute film (30 second version here) shows the process of making Factorylux electrical cable from start to finish.

The process starts with fine strands of pure copper wire. 24 strands of 0.2mm diameter are used for each core of the lighting cable. The strands are twisted together and coated with coloured insulating plastic to form the individual conductive cores - live (brown), neutral (blue) and earth (green and yellow).

What happens next depends on whether twisted or round cable is being made. For twisted or braided lighting cable, the individual cores are given a woven nylon or rayon coating before being finally twisted together. For round lighting cable, the cores are twisted together and given a further layer of insulation before the final woven coating is applied.

Each metre of three-core twisted fabric cable contains 72 metres of copper wire and 60 metres of nylon or rayon thread. The final result is safe, durable and beautiful cable.

Factorylux electrical cable comes in four varieties, each in a range of colours and fabric finishes:

- three core round fabric lighting cable

- three core braided or twisted fabric lighting cable

- two core braided or twisted fabric lighting cable

- three core core round fabric power cable

Leave a comment

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.